We are designed packages preconstructed wastewater treatment units uses integration of various treatment process to achieve clean, pollutant free treated water which can be reused for many secondary uses and with significantly lower maintenance. The treatment process is based on worldwide proven technologies however customized to create hassle free operation for users which are in form of plug and play mode. It minimizes operation issues, space requirement, construction cost and time and completely transportable worldwide. Package wastewater treatment units provides better aesthetic view of treatment units which will not fade beauty of customers premises. Treated product water quality can be optimized to highest degree as per reuse application and meeting as per local government norms. The system is fully capable of removing organic & inorganic substance, colloidal particles, suspended solids, pathogens etc.

Package Wastewater Treatment Plants (WWTPs) are pre-engineered, modular systems designed for the effective treatment of domestic and industrial wastewater. These compact plants are ideal for decentralized sewage treatment applications where space, time, and cost efficiency are critical.

Compact Design: Space-saving footprint suitable for remote, residential, or industrial sites

Pre-Fabricated Units: Factory-assembled modules ensure fast installation and minimal site work

Modular Configuration: Easy to expand or modify based on capacity and load fluctuations

Automated Operation: PLC-based or semi-automatic control systems for reliable performance

Low Maintenance: Simplified servicing and reduced operational costs

Odour-Free Operation: Enclosed design prevents odour issues

Energy Efficient: Optimized for low power consumption

Housing complexes & townships

Hotels & resorts

Hospitals & institutions

Industrial estates

Remote or temporary campsites

Educational campuses

Commercial buildings & malls

Effluent Treatment Plants (ETPs) are designed to treat industrial wastewater, removing harmful contaminants and ensuring compliance with environmental discharge regulations. ETPs play a crucial role in industries where water pollution and chemical discharge pose serious environmental risks.

To treat wastewater generated from manufacturing and processing industries

To remove toxic, non-toxic, organic, and inorganic pollutants

To ensure safe discharge into the environment or enable reuse of treated water for non-potable applications

ETPs are widely used in various sectors, including:

Textile & Dyeing

Pharmaceuticals & Chemicals

Food & Beverage Processing

Automobile & Engineering

Pulp & Paper Industry

Electroplating & Metal Finishing

Paint & Adhesive Manufacturing

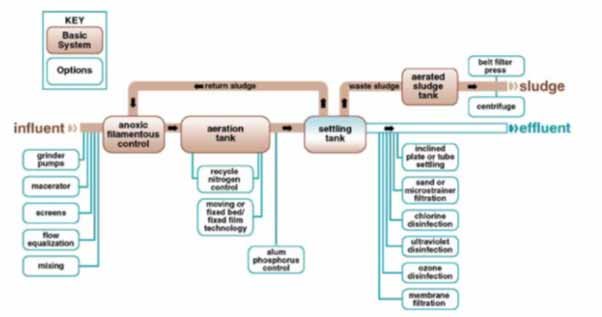

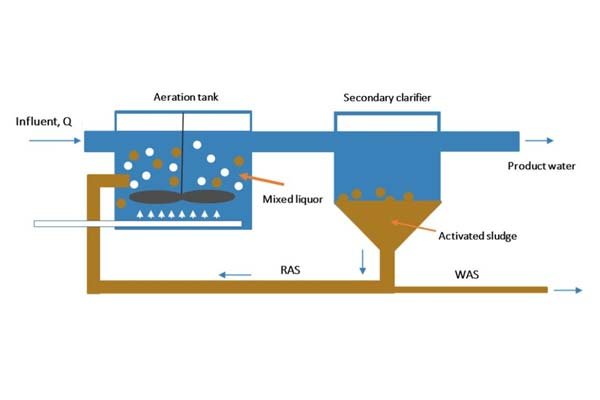

Activated sludge process for industrial and domestic wastewater treatment

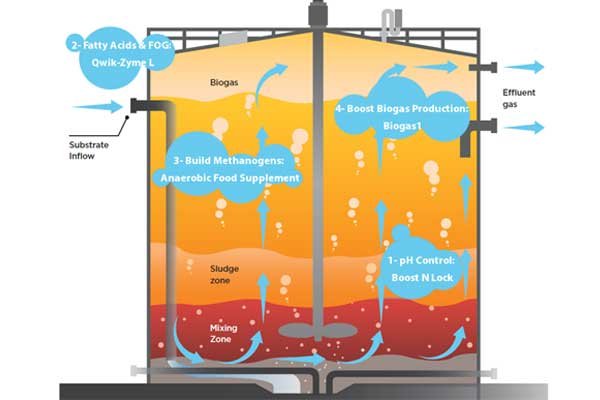

CSTR is completely-mixed form of anaerobic reactor, designed to maximize the contact between the biomass and the waste, to optimize digestion performance. CSTR digester configurations, it is also one of the best in terms of applicability to different wastes. The wastewater (wastewater/sludge mixture) enters the reactor at the bottom and leaves at the top and includes an internal recycle loop which draws reactor contents from the opposite side of the entry. Proper mixing by means of a top-entry, central agitator ensures that the influent is in constant contact with the biomass for optimal mass transfer and conversion of organic content (COD) to biogas.

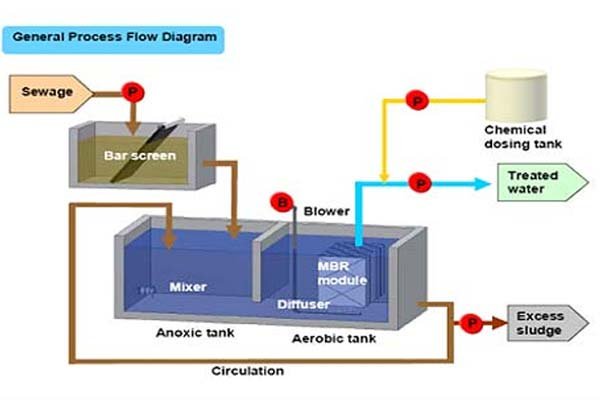

Membrane bioreactor (MBR) technology is well positioned to play a critical role in reuse applications. Technological advances of the process over other wastewater treatment process is as efficient and effective. From retrofits to decentralized plants, MBRs are a versatile treatment platform that can help change perception and turn wastewater into a viable resource. When looking into advanced water reuse applications, MBRs represent the best product quality for reuse application in smallest footprint.

Whatever your water or wastewater challenge, we can develop a solution for you. Get started by getting in touch with one of our experts.

At Techno Tech Aqua ., we strive for excellence in meeting the evolving needs of our valued customers. With a forward-thinking mindset and a strong foundation of trust, we deliver innovative, future-ready technologies that ensure sustainable and efficient water solutions.

Copyright © Techno Tech Aqua Group. 2025 All Right Reserved |Website Developed by Flown Developer